The DTF Transfer Gang Sheet is a cost-effective, multi-design printing solution that simplifies custom printing for businesses. By eliminating plate-making, it offers versatile printing on thin, flexible material. For optimal results, maintain a clean workspace, follow specific design guidelines, and apply color theory to prevent ink blending. Prepare designs in PDF/JPEG with 300 DPI resolution using software like Adobe Illustrator or InDesign, ensuring precise file setup for high-quality multi-color prints. This guide outlines the steps for efficient production of custom apparel or product branding through DTF printing.

Learn the art of maximizing your print potential with DTF (Direct to Film) Transfer Gang Sheets. This versatile method allows you to print multiple, diverse designs on a single sheet, streamlining production and reducing waste. From understanding the unique properties of DTF sheets and gathering the right materials, to designing for seamless multi-color prints and following a step-by-step guide for efficient output, discover how to unlock the efficiency and creativity of DTF Transfer Gang Sheets.

- Understanding DTF Transfer Gang Sheets: Materials and Setup

- Designing for Multi-Color Prints: Tips and Tricks

- Step-by-Step Guide: Printing Multiple Designs Efficiently

Understanding DTF Transfer Gang Sheets: Materials and Setup

A DTF Transfer Gang Sheet is a specialized printing medium designed for efficient multi-design printing on a single sheet. Comprising a thin, flexible material, it allows for the precise application of inks and ensures consistent quality across all prints. The sheet is typically composed of two primary layers: a base layer that supports the design and a top coating that facilitates ink transfer. This innovative approach eliminates the need for traditional plate-making, making it an attractive option for businesses seeking cost-effective custom printing solutions.

When setting up for DTF printing, understanding the material’s characteristics is key. Ensure your workspace is clean and well-ventilated due to the volatile nature of the inks. Prepare your designs according to DTF application instructions, ensuring they meet specific resolution and file format requirements. Custom DTF gang sheets offer a degree of flexibility, allowing you to experiment with various design arrangements on a single sheet while adhering to the essential dtf design requirements for optimal print quality.

Designing for Multi-Color Prints: Tips and Tricks

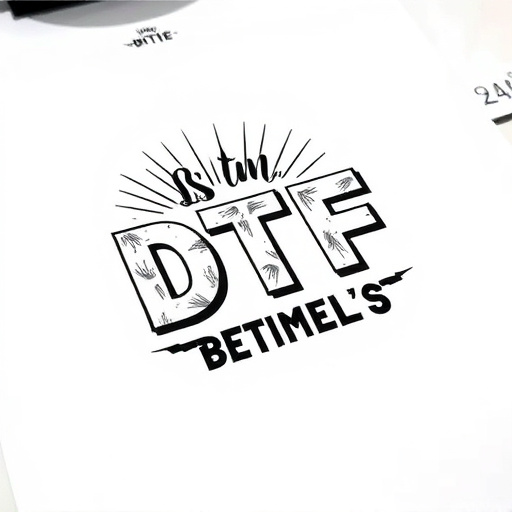

When designing for multi-color prints using a DTF Transfer Gang Sheet, it’s crucial to consider color theory and placement to ensure seamless transitions between inks. Start by breaking down your design into individual color components, allowing ample space between each to avoid blending or visible lines when printed in sequence. This separation is key to achieving durable prints.

During the DTF file preparation stage, optimize your graphics for the unique properties of this method. Ensure all elements are vectorized and set at a suitable resolution for printing. The DTF curing process demands precision, so careful file setup minimizes potential issues later on. Remember, proper alignment and consideration of registration marks will result in a high-quality, multi-color print on your DTF Transfer Gang Sheet.

Step-by-Step Guide: Printing Multiple Designs Efficiently

Printing multiple designs on a single DTF Transfer Gang Sheet is an efficient way to reduce costs and maximize productivity for custom apparel or product branding. Here’s a step-by-step guide to help you navigate this process seamlessly:

1. Design Preparation: Start by ensuring all your designs meet the required DTF printing services specifications. This includes file format (usually PDF or JPEG), resolution (300 DPI minimum), and design layout, considering the size of each design in relation to the gang sheet dimensions. For smaller orders, DTF small orders often provide an easy solution without requiring complex setup.

2. Layout Design: Utilize graphic design software like Adobe Illustrator or InDesign to arrange your designs on the gang sheet. Each design should be placed precisely, with careful consideration of bleed areas and trimming lines to ensure accurate printing. Remember that the layout needs to accommodate the minimum space between each design for efficient cutting and weeding later.

3. Pre-press Check: Before sending your file to print, perform a thorough pre-press check. Verify color accuracy, design alignment, and overall quality. Ensure all fonts are embedded and linked properly to avoid any last-minute glitches during printing.

4. File Upload: Upload your final layout file to the printer’s designated platform or email it directly, adhering to their specific guidelines. Some printers offer online platforms where you can upload designs, view proofs, and track your order status.

5. Printing Process: Once approved, the DTF printing services team will print your designs onto the transfer sheet using high-quality equipment. The gang sheet is then cut precisely according to each design, ready for application to various products.

Printing multiple designs on a single DTF Transfer Gang Sheet is an efficient way to save time and resources, especially for small businesses or hobbyists. By understanding the materials and setup required, and implementing design tips tailored for multi-color prints, you can achieve professional results. Following our step-by-step guide ensures a smooth process, allowing you to experiment with diverse designs while maximizing your printing potential.