DTF Transfer Gang Sheets revolutionize small print businesses by offering unparalleled customization and efficiency in DTG printing. Crafted from specialized materials, these sheets eliminate costly screening processes, cater to bulk orders and personalized small batches, enhance consumer satisfaction with rapid delivery, and streamline workflows through batch processing, simultaneous printing, and curing. Regular equipment calibration ensures consistent quality as businesses optimize the DTF transfer process for growing demand without compromising outcomes.

For small print businesses seeking a competitive edge, embracing cutting-edge technology like DTF (Direct To Film) Transfer Gang Sheets can be transformative. This innovative solution revolutionizes printing processes by enabling efficient batch production of high-quality prints on various materials.

This article explores the ins and outs of DTF Transfer Gang Sheets for printers, highlighting their benefits in streamlining operations and boosting productivity while offering a cost-effective alternative for small businesses in the print industry.

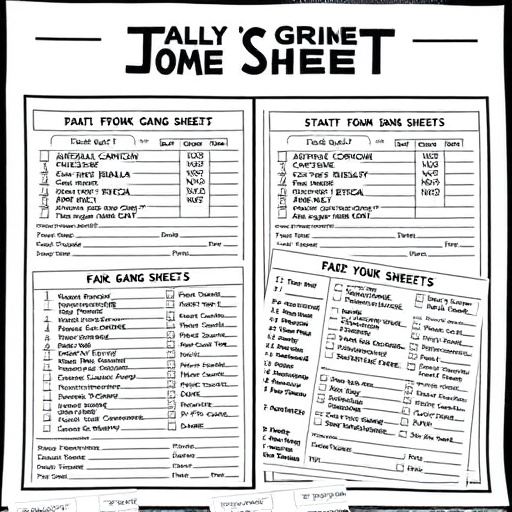

- Understanding DTF Transfer Gang Sheets for Printers

- Benefits for Small Businesses: Streamlining Operations

- Implementing and Optimizing DTF Transfer for Efficiency

Understanding DTF Transfer Gang Sheets for Printers

DTF Transfer Gang Sheets are a game-changer for small print businesses looking to streamline their operations and offer a wide range of customization options. These sheets are specifically designed for direct-to-garment (DTG) printing, enabling entrepreneurs to easily apply intricate designs and graphics to various garments with precision and speed. By utilizing DTF Transfer Gang Sheets, small businesses can cater to both bulk orders and the growing demand for personalized, small-batch production, ensuring they stay competitive in the market.

Understanding the fundamentals of DTF Transfer Gang Sheets is crucial for printers aiming to deliver high-quality results with efficiency. The sheets are made from a special material that allows ink to transfer directly onto fabrics, creating vibrant and long-lasting prints. This method eliminates the need for costly screening processes, making it an attractive option for small orders and urgent deliveries. With fast turnaround times and the ability to handle complex designs, DTF garment printing ensures that businesses can meet the expectations of modern consumers who seek unique, customizable clothing options with rapid delivery, hence enhancing their overall satisfaction.

Benefits for Small Businesses: Streamlining Operations

For small print businesses, adopting DTF Transfer Gang Sheets can significantly streamline operations and boost efficiency. This innovative technology revolutionizes traditional printing methods by enabling batch processing of custom orders, a game-changer for businesses handling numerous dtf custom orders daily. The dtf curing process becomes more manageable as these sheets allow for simultaneous printing and curing, reducing turnaround time and enhancing productivity.

By implementing DTF Transfer Gang Sheets, businesses can efficiently manage their workflow, moving from design to production promptly. This streamlined approach not only satisfies customers’ demands for quick turnaround times but also empowers businesses to handle increased order volumes without compromising quality. Moreover, it simplifies the process of creating custom designs, making it easier to cater to diverse client needs and stay competitive in the market.

Implementing and Optimizing DTF Transfer for Efficiency

Implementing DTF Transfer Gang Sheets for small print businesses is a strategic move to streamline operations and enhance efficiency. These sheets are designed to accommodate multiple prints on a single substrate, enabling batch production that saves time and costs. By optimizing the DTF (Direct to Film) transfer process, small businesses can meet increasing demand without compromising quality.

DTF design requirements focus on precise alignment and meticulous detailing to ensure accurate transfers. Utilizing specialized DTF logo transfers and high-quality transfer films ensures crisp, vibrant prints. Optimizing the setup involves considering factors like printing speed, film tension, and ink viscosity. Regular calibration and maintenance of equipment also play a vital role in maintaining consistency and efficiency throughout the production process.

For small print businesses looking to enhance their operations, DTF Transfer Gang Sheets offer an efficient and cost-effective solution. By understanding and implementing this technology, businesses can streamline production processes, reduce waste, and improve overall productivity. The benefits are clear: faster turnaround times, higher quality prints, and a competitive edge in the market. Embracing DTF Transfer Gang Sheets is not just a step towards modern printing practices; it’s a strategic move to stay ahead in today’s dynamic business landscape.